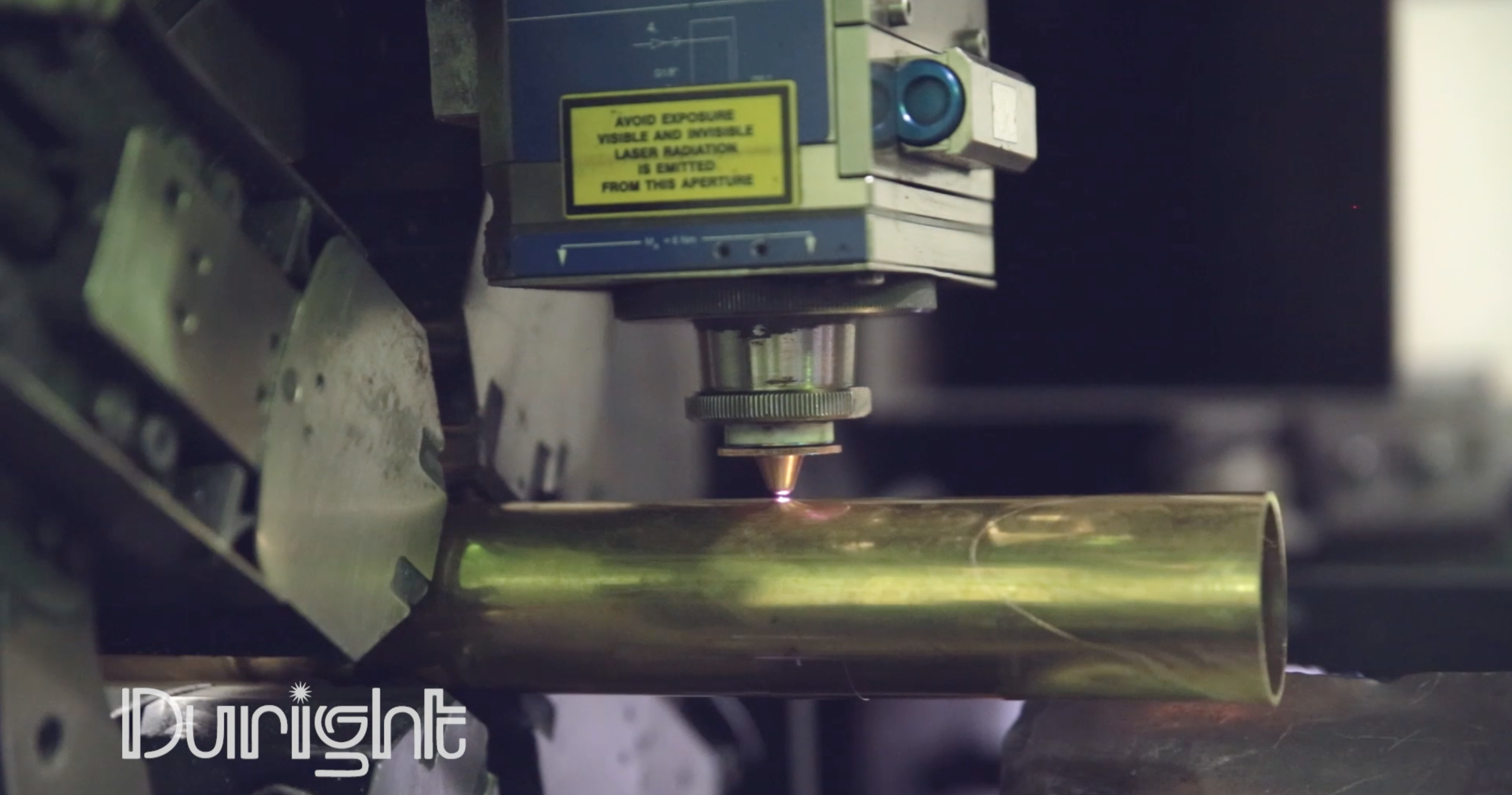

Laser Tube Cutting Specialists

Utilizing 4 tube laser cutting machines.

Batch sizes range from one off’s to 500,000 and cover sections and diameters from 4mm to 154mm.

The Adige TC720

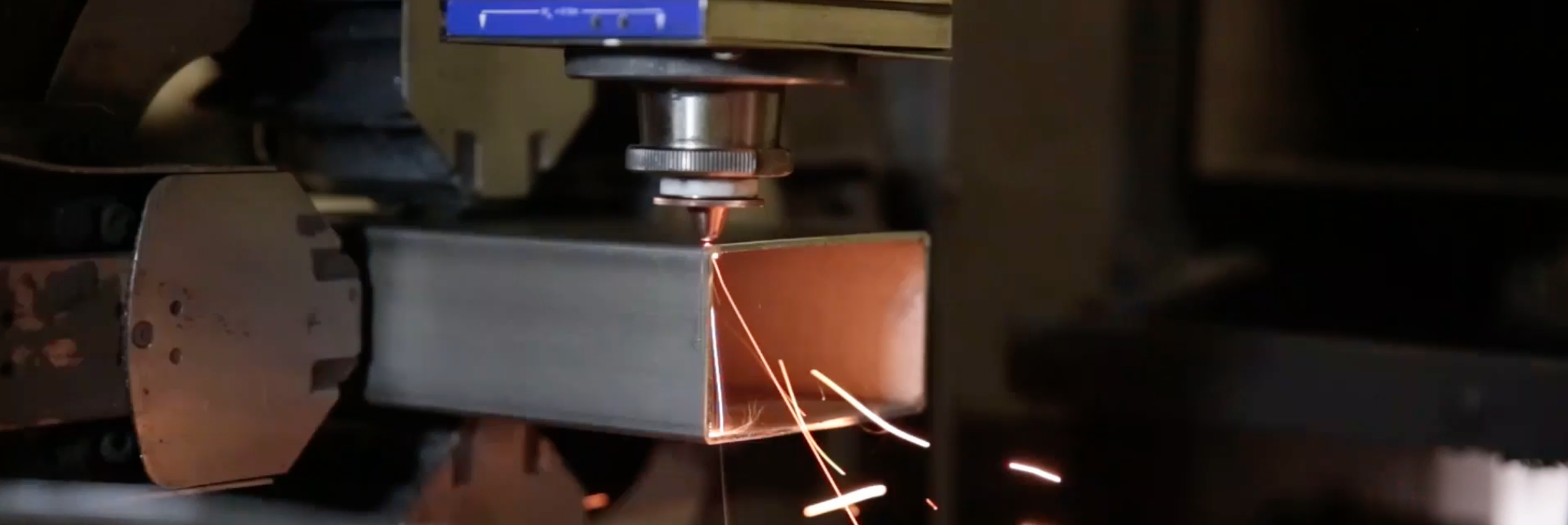

We have increased our turnover over each year for the last 25 years, largely due to the cutting capacity of our Adige Lasers and high-speed automatic production saws which produce more than one million cuts per month.

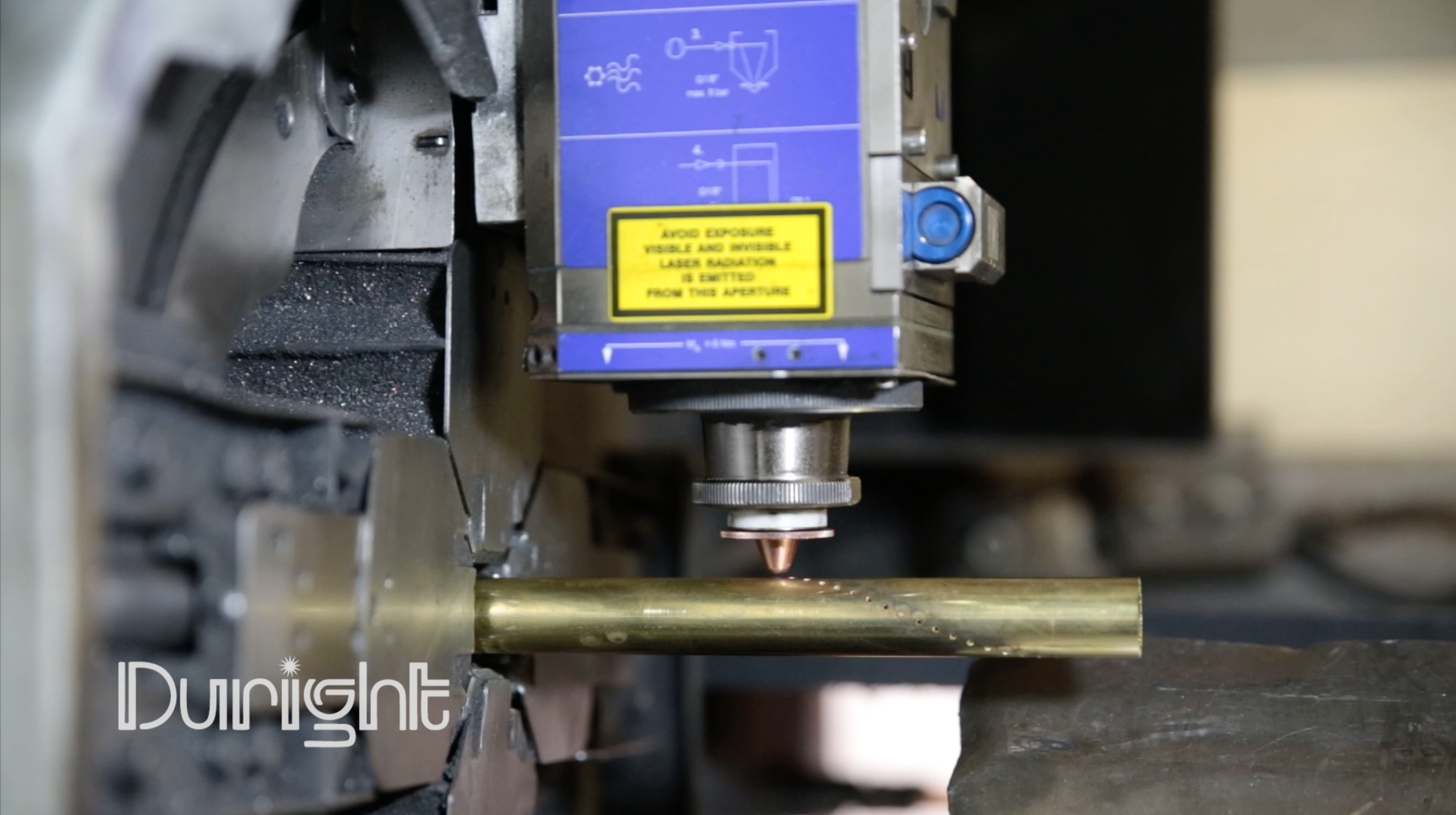

We are able to process tubes up to 8.5 mtr’s in length.

We currently run our three laser cutting machines on a 3 shift system enabling us to offer our customers next day turn around on most jobs.

With a change over time of less than two minutes, the new Lasers have proved to be highly cost effective, enabling us to keep prices low.

That’s why it makes sense to talk to Duright Engineering

Find out more

Call: 0121 556 7718

Email:

Please note: your call may be recorded for training or monitoring purposes.

What sets Duright apart from our competitors?

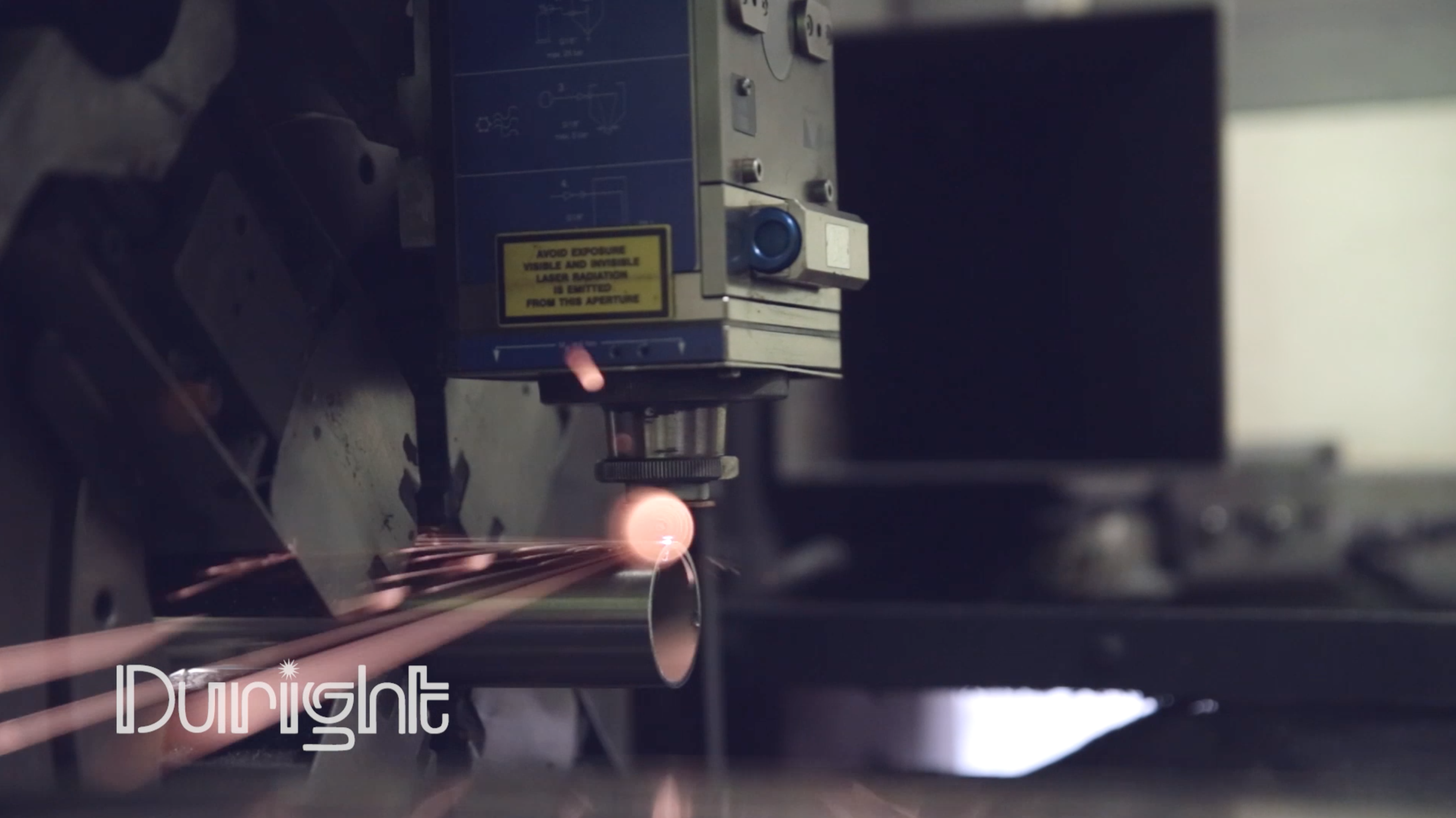

- We continually invest in the latest laser cutting technology to provide the highest quality cut parts

- We can provide local and nationwide deliveries

- Open 24-7 offering impressive lead times and turnarounds

- We can process a wide range of tube from 3.5mtr’s in length up to 8.5mtr’s

- We don’t just supply tube. For nearly 40 years we have provided a high quality of service throughout our production process, by organised, highly trained, skilled Engineers

Latest News

Duright Expanding Operations with New LT FIBER

Duright engineering are excited to announce the installation of our New ADIGE LT FIBER tube laser. Due to ongoing growth Duright have now expanded with a new 35000 Square feet unit that homes our state of the art machinery. The unit is completely geared up for fast paced production ideal for the automotive sector with […]

Twitter

Twitter: durighteng